HEATING BUILDINGS IN INDUSTRY AND COMMERCIAL

SUN-BEAM

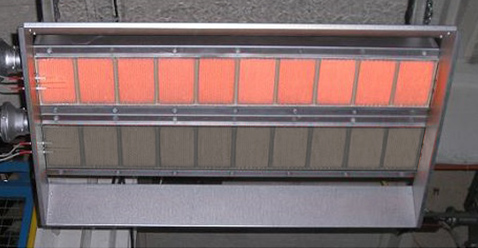

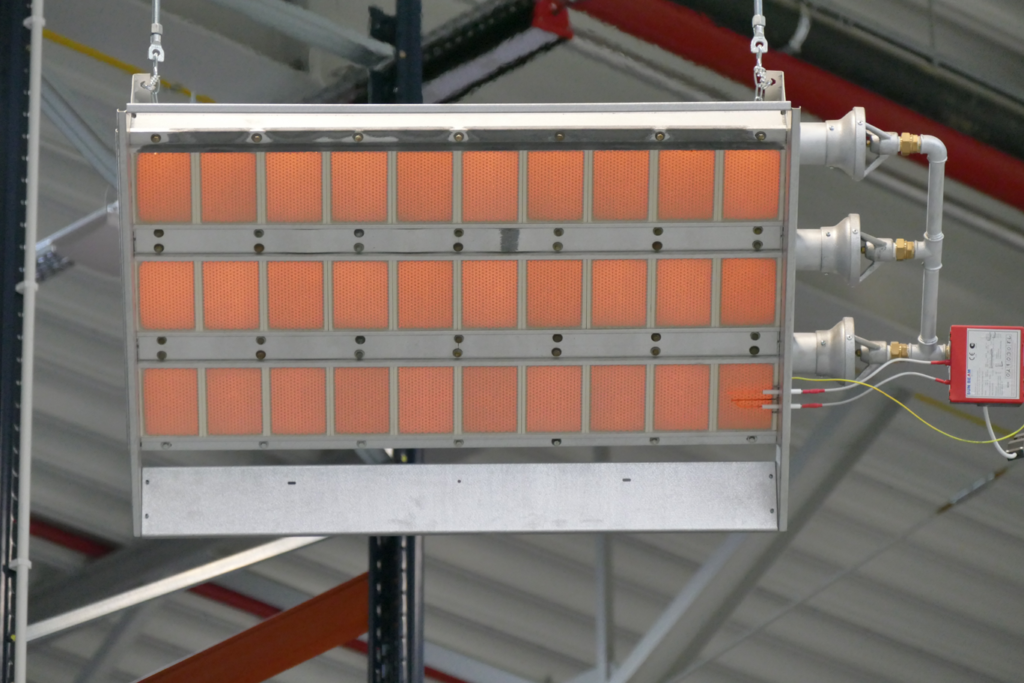

CERAMIC GAS HEATER SBC

Ceramic gas heater SBC

It is used in high rooms. It is perfect for local (spot) heating. Our models start at 5.7 and end at 42.8 kW. It is a heater with an open combustion chamber, in which the gas-air mixture is burned on the surface of the ceramic plate. The air needed for combustion is taken from the room, therefore the hall with ceramic heaters should be well ventilated (10 m3 / h per 10 kW of installed power).

Ceramic gas radiators are used in such facilities as:

- Industrial halls, workshops, factories, sheds

- Churches, mosques

- Sports halls, sports fields

Ceramic heater

It is a heating device with an open combustion chamber in which a gas-air mixture is burned on the surface of a ceramic plate. The air needed for combustion is taken from the room and the exhaust gases are discharged into it, therefore the room in which ceramic heaters are installed should be properly ventilated. The radiator’s body is made of durable, corrosion-resistant materials, which ensures many years of failure-free operation even in conditions of increased air humidity.

Advantages of radiant heating

ENERGY SAVING

Fast start-up times and an immediate heat effect allow for efficient use of gas and lower heating costs

HIGH LEVEL OF SECURITY

It is provided by a solenoid valve together with an electronic controller that prevents uncontrolled gas leakage

APPLICATION FLEXIBILITY

Buildings can be partially heated in designated areas where people stay in a given period of time without the need to build partition walls

NO AIR MOVEMENT

The radiator does not have any moving parts or fans, which does not cause additional movements of dust in the heated room

RELIABILITY OF DEVICES

The radiators have been tested to ensure high quality and to guarantee their proper operation

TWO-STAGE RADIATORS

Allow for flexible adjustment of the power of the radiators to current needs

TECHNOLOGICAL APPLICATION

Ceramic radiators are perfect for technological applications, e.g. for drying or heating materials in order to maintain their appropriate physical properties

AUTOMATIC ADJUSTMENT AND SIMPLE OPERATION

The heaters can be equipped with an automatic time-temperature controller that allows you to control the operation of the heaters in a weekly, day / night, winter / summer mode

LOW INVESTMENT AND EASY INSTALLATION

thanks to the fact that the flue gases from the radiator are discharged directly into the heated room, there is no need to install additional ventilation ducts, which reduces costs and shortens the installation time of ceramic radiators

Infrared heating

The photo shows an example of heating an industrial factory with SBC ceramic gas heaters. By retrofitting the factory’s heating with Sun Beam gas heaters, the facility user saves 70% per year on heating bills. The investment in a radiant heating system will pay for itself in this case within 3 years. Gas radiators are powered by natural gas and have the option of zone heating. This means that they can be turned off in part of the building and the rest can be heated.

Two-stage radiators

The radiant heating system has the highest gas consumption at full load, which is only required a few days a year. Two-stage regulation allows you to adjust the power of the radiators to the current heating demand.

Moreover, the thermal comfort of the object is improved.