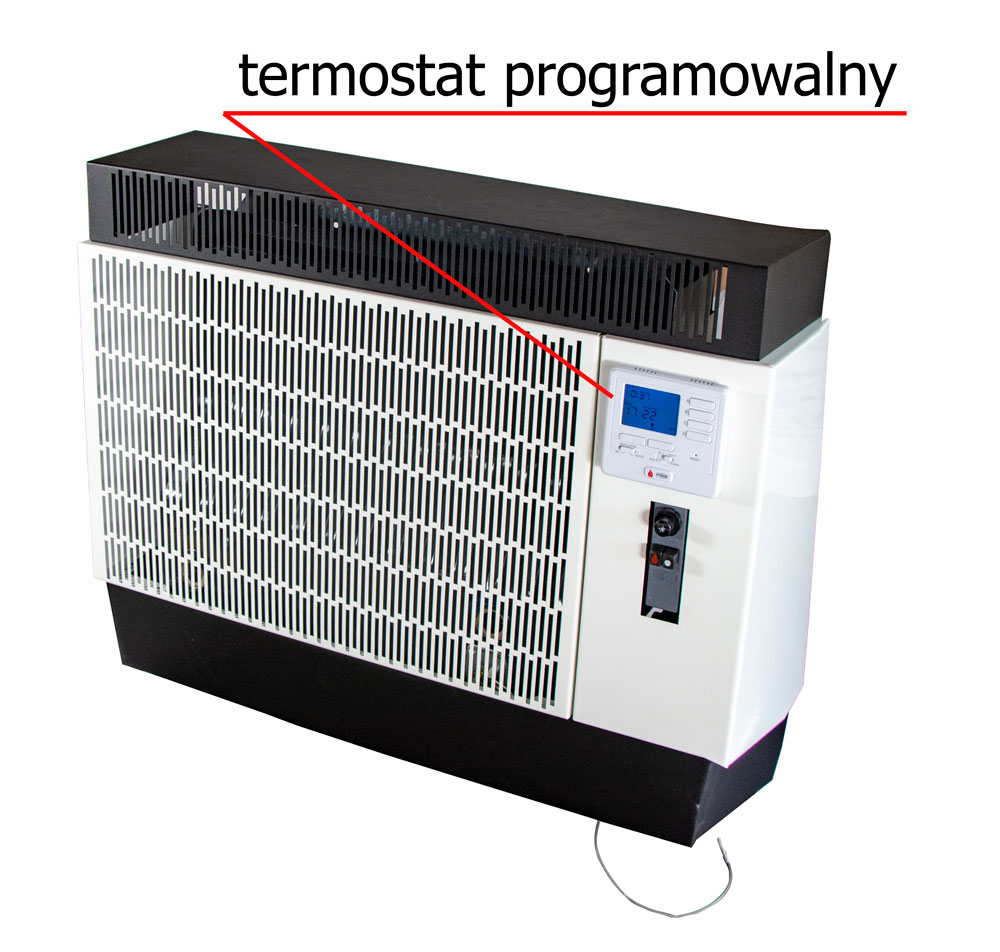

Gas stoves with a programmable weekly thermostat

Our offer includes a new series of RGH gas stoves with flue gas discharge. Gas heaters were created especially for our shop piecykigazowe.com.pl. They were produced by the renowned Hungarian producer FEG. It has been producing gas stoves for 50 years. Gas stoves with LPG cylinder or natural gas available at this address: FEG gas stoves

Gas stoves with flue gas discharge

A gas stove with flue gas discharge is a local heating device. This means that its task is to heat the room in which it is located. This room heater heats the closed combustion chamber by burning a mixture of gas and air. Then it gives off heat by convection. Hence the name gas convector.

The RGH flue gas convectors are equipped with a thermostat. It is programmable weekly or on selected days. This allows for precise temperature control in each room in which the stove is located. Added to this is the fact that when heating many rooms, we can heat them independently of each other. This is an immediate difference in gas consumption and therefore in costs. With conventional radiator heating from a gas boiler, this is usually very difficult and time-consuming. Heating with gas room heaters enables one room to be heated.

The efficiency of FEG gas heaters reaches 93-95% (class A). This is a very good result. With the pilot flame lit, the device continues to heat the room. Thus, the heat of the pilot flame is useful for local heaters. Consider the efficiency measured under the pilot flame load. The efficiency at the measured pilot flame load is 2-3% higher than when measured without taking into account the heat from the pilot flame.

Construction and operation of a gas stove with an electronic thermostat

A gas stove with flue gas discharge consists of a closed combustion chamber – it is a hermetic space in which gas burns. It is steel and enameled, which guarantees its durability. There is a burner in the closed combustion chamber. The burner has a so-called pilot flame. This is the element that shows if the room heater is working. Because it burns when the burner is turned off, it gives off heat. This reduces fluctuations in the measured temperature and enables rational gas consumption.

Another element is the valve . Controls the amount of gas supplied to the closed combustion chamber in the gas convector. The valve receives signals from the thermostat , which tells it when and how much to deliver gas. The gas can come from cylinders or from natural gas installations or an external LPG tank. As mentioned earlier, the thermostat is programmable weekly or for selected days – this means that the only activity at the stove may be to change the LPG cylinder.

The RGH series gas heater is equipped with a piezo ignition. It is a magneto powered by AA batteries. The gas stove fires up quickly and easily.

The next element is flue gas discharge. It is a double chimney, commonly known as a pipe in a pipe. Air is taken in through the outer tube. The exhaust outlet is routed through the inner pipe. As a result, the chimney temperature is lower, which facilitates insulation.

Comparison

Gas stoves and boilers

Heating rooms with a gas convector may turn out to be cheaper in many cases. This is due to the ease of installation and the total energy consumption, which in total are cheaper! Of course, it is important to investigate which solution is better in each case. Our employees available at +48 41 362 40 26 can help in this .

Using a gas boiler or a gas combi boiler is more economical if we need to heat the entire building during the heating season. And also maintain the optimal temperature. However, the building must be large enough for boiler heating. In the event that we need to quickly heat up a part of the building – e.g. hotel rooms, offices, places, etc., it is worth considering gas stoves with a cylinder.

Gas convectors are especially recommended for buildings that are used partially or during some part of the day. In a situation where the room heater is periodically turned off, the thermostat from the gas boiler heating system will register this change, so in order to compensate for it, the other turned on room heaters will heat up more.

The advantage of a gas stove is that it will heat one room in 30 minutes. Speaking here on heating from a low temperature of 10 ° C . In the case of radiator heating it is practically impossible, the more so as the temperature of the heating water in the radiators is adjusted to the actual heat demand of the room. Thus, the temperature of the heating water is only sufficient to keep the thermostat room warm, but not sufficient to heat, for example, a cold work room. If you know that you will need to heat the rooms quickly, and additionally there is no permanent access to electricity, seriously consider gas cylinder heaters.

The situation is similar to that when changing the set room temperature, for example when using a program clock. The extra power needed for heating can be obtained by switching the gas boiler to a much higher power than that required to maintain a constant temperature. This leads to an increase in the temperature of the heating water. In this case, the efficiency of condensing boilers will no longer be optimal. To check this, only the officially released technical data of condensing boilers should be taken into account.

The same situation with the gas convector works in its favor. The efficiency of the gas heater is best at full power. Therefore, the temporary temperature reduction and the associated savings are higher than the costs of reheating. Condensing boilers require a higher temperature of the heating water, and therefore power. This lowers the boiler’s efficiency and drastically increases fuel consumption.

Efficiency of gas stoves

The seasonal efficiency of class “A” flue gas stoves and condensing boilers is almost the same.

As a result of the above, gas convectors can achieve the energy efficiency level “A” in accordance with Regulation No. 1186/2015 / EU. We can also achieve very good seasonal efficiency of more than 88%. This is the minimum to achieve the “A” energy efficiency level for gas stoves. Seasonal efficiency of a gas boiler should be at least 90%, which is the minimum for “A” class. Efficiency measurements should always be made in accordance with the relevant European standard for gas appliances. Seasonal efficiency of heating appliances for gas boilers is determined by the formula provided in Regulation (EU) 811/2013. This shows that the information about the low efficiency of gas cylinder or plant-powered stoves is incorrect.

It is worth noting that in order for a given equipment to reach “A +”, it must at least partially use energy from renewable sources. Unfortunately, this is not possible with either condensing gas boilers or gas heaters.

Below we present a gas stove with energy efficiency class “A”.

Our RGH 5.9 kW convector with a programmable thermostat has the A energy class. Without a programmable weekly thermostat, the gas convector can achieve an energy class of at most B. The gas convector’s combustion chamber is made of enamelled steel. In addition to the gas convector itself, the manufacturer also provides flue gas discharge. Flue gas discharge and air intake with one double chimney. The chimney is also enameled.

Noteworthy technical information about the gas heater:

- Before installation, check the tightness of doors and windows

- Read the instructions for installing the chimney to the wall, especially if there is additional insulation.

- Only factory parts may be used to extend the attachment of the chimney to the wall. Flammable walls should be replaced with brick walls at least as thick as the chimney

- In the case of brick walls with cavities, make mineral wool insulation and plaster around the wall chimney to achieve airtightness

- On the outside of the building, additional thermal insulation must be non-flammable.

- The insulation should be resistant to a temperature of at least 250 ° C at a distance of 300 mm from the exhaust gas outlets.

- The wall around the wind cage should be flat. It is not allowed to form conical or rectangular recesses.

- The position of the wall mounting in relation to the center of the device module is given in the manual. Do not reduce the gap between the rear of the gas convector and the wall.

If you have any questions, please contact our employees at +48 41 362 40 26 .